Engineering & Building kit information

Build preparation, Engineering & Building Kits

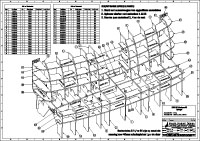

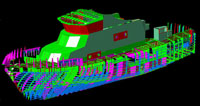

When the design is (almost) ready, often is started with the building preparation. Part of that can be a full engineering package from the construction of the vessel. Included in the design normally a construction plan is included with some typical details. Shipyards used to build the ship from this plan and some additional information like a 1:1 scale frameplan. That meant that the shipyard had to do a lot of work on the lofting floor and figure out themselves how every structural part had to be made. These days modern and specialised software can be used to do a lot of that building preparation. Practically the vessel can be build completely in the digital world and in principle the exact dimensions of every part can be designed. Modern CAD/CAM systems using computer controlled routers, plasma, laser and even high pressure water cutters, can cut plywood, foam, aluminum and steel with an accuracy of a fraction of a millimeter. This could be done for temporary building frames or actually all the final parts to be used in the building proces. Guided with detailed assembly drawings the building kit can be assembled by the shipyard. This saves enormous amounts of time on the shopfloor. Also with these computer cut parts the shape of the vessel is very precise and it's much easier to make a fair hull. With a building kit even building your own boat as a private person is much less of a challenge.

Yard Standard & Custom Build Kits

Shipyards often have their own work and construction standards. These yard specific standards can perfectly be incorporated in the building kit. This way the craftsmen on the shopfloor don't get unpleasantly surprized by 'exotic' creations by the designer and the building proces will be smooth and easy. This saves of course a lot of time and money.

A building kit or cutting package can be used for building the hull of a ship but also to prefabricate the interior! There is a lot of different materials which can be used. Just to name a few:

- Steel

- Aluminum

- FRP

- GRP

- Composite Cored structures (Foamcore, woodcore)

- Plywood

- Solid wood

Every material has it's own requirements in processing but with every building method a building kit of some sort can be usefull. With composite and plywood boatbuilding many times building frames are used, espacially with 'one-offs' or custombuilds. These can easily be made from MDF (medium density fibreboard) which is stiff enough for the purpose and it is not expensive. For plywood, steel and aluminum boats a complete building kit can be provided which contains all the necessary parts to build the boat. On the right side of this page you can see some examples.

What do you get when you order a building kit?

Depending on what detailing level is requested by the client a building kit or cutting package can come with the following information:

- 2D/3D detailed assembly drawings with dimensions

- Shopfloor drawings with part identification, position and dimensioning

- Shopfloor drawings with plate expansions and/or folded parts

- Forming information (for example with a roundbilge hull)

- Step by step building strategy plans

- Building frame information

- Plate Nests, optimized for efficient material usage

- Profile reports, overview of used extrusion profiles with type, lengths and end-cuts

- Part reports, overview of all cut parts with information like plate thickness and weights

- Nest reports with specific information (e.g.amount of plates and remnant info)

- Exact weight information and centre of gravity for building sections or in total

- 1:1 scale frameplan plotted on MDF or on Mylar (foil)